The track season is now in full swing and you may be considering giving the track a go but you’re unsure as to what to expect and how your MINI will perform. There are a few things that you need to know and do a little preparation for in order to enjoy the track day. We will gear the article towards the person who has not been on track previously but is keen to have a go and we will assume that your MINI is a standard car and used for regular but enthusiastic road driving.

If you are an experienced track day enthusiast please get in touch with Lohen to discuss any requirements.

HEAT PROBLEMS

Your biggest foe on track is heat. Heat build up happens so much faster as you are pushing the car so much harder than you would otherwise.

Excess heat builds up in the following key areas

- Brakes

- Oil

- Water

- Intake temperatures

- Tyres

BRAKES

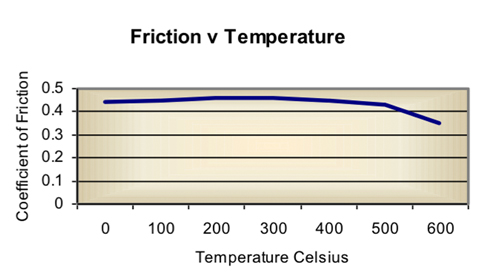

Brakes have an optimal operating temperature; extended track use pushes temperatures higher than this optimal operating temperature, which is experienced on the road, so braking performance declines. Whether you are a newcomer to the track or a seasoned pro, having effective brakes will allow you to have confidence in the car and enjoy the day. It is also a major safety component so needs to work for the safety of you and other track users.

It is therefore important to introduce components that perform well at the higher operating temperatures or help to dissipate the heat better than the stock items.

So what can you do to improve braking performance and endurance on the track day?

First stop is brake fluid. The MINI uses a DOT 4 fluid as standard, which has a boiling temperature of around 155C depending on specification. Changing this for a high quality DOT 5.1 brake fluid, such as the AP Racing fluid, which has a boiling temperature of around 190C depending on specification, will help to maintain your brake pedal feel and braking performance for longer. Installing the DOT 5.1 will not damage brake seals, it is compatible with the DOT 4 systems. The cost of a quality brake fluid change at Lohen is £69. Using an AP600 Racing fluid will further increase boiling temperatures of the brake fluid and is compatible with the MINI system, however die to the nature of the 600 grade fluid it will require more frequent service intervals.

The next option available is to install a performance brake pad where the optimal performance temperature is higher than the stock pad. It is not simply a case of installing a race pad as cold braking performance on this sort of pad is often poor and they are not E marked for road use. Lohen favour a Mintex M1144 brake pad in all MINI’s for fast road and occasional track use. This is because the compound delivers a strong cold bite that is maintained through higher operating temperatures than the stock pad.

Brake discs also play an important role in braking performance. For improved braking performance and endurance ideally you’d choose a thicker and a larger diameter disc but this is not possible due to restrictions on the calliper. To maintain braking performance a good quality drilled and grooved discs help shed brake dust and increases surface area marginally to help dissipate heat.

Replacing the standard fit rubber brake hoses for a stainless steel braided brake line, such as a Goodridge hose, is another relatively inexpensive upgrade that produces a firmer and more reliable pedal feel as the braided hose does not expand and contract in the same way as the standard hose. A set of front and rear Goodridge hoses from Lohen are £85.00.

ENGINE OIL

Engine oil will be subject to high temperature cycles during a track event so having engine oil of good quality and good condition is key to maintaining a healthy engine. It is important to check oil levels prior to starting the track event. A fresh oil engine and filter change prior to the event will ensure the oil is at its optimal condition and can therefore function to its optimal level. Lohen would suggest a high quality fully synthetic oil, we favour a Millers XF Longlife 5W30 for most standard engine applications. The high temperature cycles experienced on track would benefit an oil change service following the track event too. This is particularly important in Generation 2 and 3 turbo models due to the heat generated in the turbo.

The MINI’s cooling systems will be on overdrive during a track day so its key that its working at its best and the correct level of fluid is installed. A waterless coolant can be used in place of the standard water based coolant. A product such as Evans Power Cool 180 is a waterless product that has a boiling point of above 180C, which is greater than most water based coolants. This increased capacity reduces the pressure build up as a result of steam/vapour meaning there is less chance of boil over and coolant loss. A coolant change using Evans Power Cool 180 is £150 at Lohen.

INTAKE TEMPERATURES

As the MINI is run harder and under bonnet temperatures increase, intake temperatures also increase. Keeping intake temperatures low is important to maintain performance. There are sensors on the MINI that monitor intake temperatures. When intake temperatures exceed a given value the MINI’s ECU retards the ignition and therefore power is reduced. High intake temperatures can also induce knock, which is damaging to the engine. We will leave that topic for the future as it’s outside the scope of this article but you can always give Lohen a call to discuss further if you wish.

For naturally aspirated Generation 1 and 2 MINI One and Cooper installing a cold air intake system is an option to reduce intake temperatures. Lohen offer a Pipercross Viper kit for £202 that offers direct cold field for the MINI Gen 1 One and Cooper. For boosted MINI’s such as the Cooper S and JCW variants installing an uprated intercooler is a great option. Uprated intercoolers tend to have increased surface areas and higher quality intercooler cores that are more efficient at dissipating heat so produce lower intake temperatures than using the stock items. It’s important to install a good quality unit. For the Generation 1 Cooper S and JCW an Airtec or GRS Motorsport intercooler are great options. For the Generation 2 and 3 Cooper S and JCW try the Airtec or Forge options. Forge has recently released an option for the Generation 3 Cooper, which is a quality unit. Prices start from £395.

DO’S AND DON’TS

- Do warm up. Get a couple of slower laps in and gradually apply heat to the brake system. Doing this will help avoid glazed and/or warped discs. This also allows engine fluids to get to optimal operating temperature and avoid engine damage.

- Do cool down. Take a lap at half speed to get air over the brake system this will help dissipate some of the stored heat. The same applies for the engine and turbo.

- Do give the brake pedal a pump before going out for the next session.

- Do check your coolant and oil levels prior to the event

- Do check tyre pressures. Set to around 32 PSI when hot and monitor these through the day.

- Do check tyre pressures after completing the track day and setting off home. These will reduce as the tyre cools.

- Do check wheel nuts after the first session, heat and the stress of the track can work these loose. Ideally torque wrench and torque to 120 Nm Generation 1 MINIs and 140 Nm Generation 2 MINIs

- Don’t stand on the brakes hard from cold if you can avoid it

- Don’t rest your foot on the brake pedal or apply the hand brake in the pits wherever possible. This will help avoid warped discs and reduce heat transfer from the discs to the brake fluid.

You will notice power increases have not been discussed and while this might be seen as boring it is necessary to tackle the areas discussed prior to power increases in order to enjoy the tack day to its fullest. Power increases will only exaggerate the heat build up, produce problems, reduce track time and your enjoyment.