Generation 2 MINIs use a correction-based servicing system – in effect your MINI’s on-board computer will alert you when components need attention. That said, if you prefer to service your New MINI regularly, you could adjust your MINI servicing intervals to suit your needs. Generation 2 MINIs have direct injection engines and, as such, suffer from coking of the inlet valves, which is particularly obvious on Cooper S & JCW models. Over time this coking can lead to a loss of power and hesitation so Lohen recommends you factor in regular engine de-coking a part of your Gen 2 MINI’s servicing schedule.

We offer walnut shell blasting and use dealer standard equipment meaning you’re guaranteed a perfect result every time. We can even dyno your car before and after the de-coke to show the improvement in power and torque.

MOT Testing Facilities

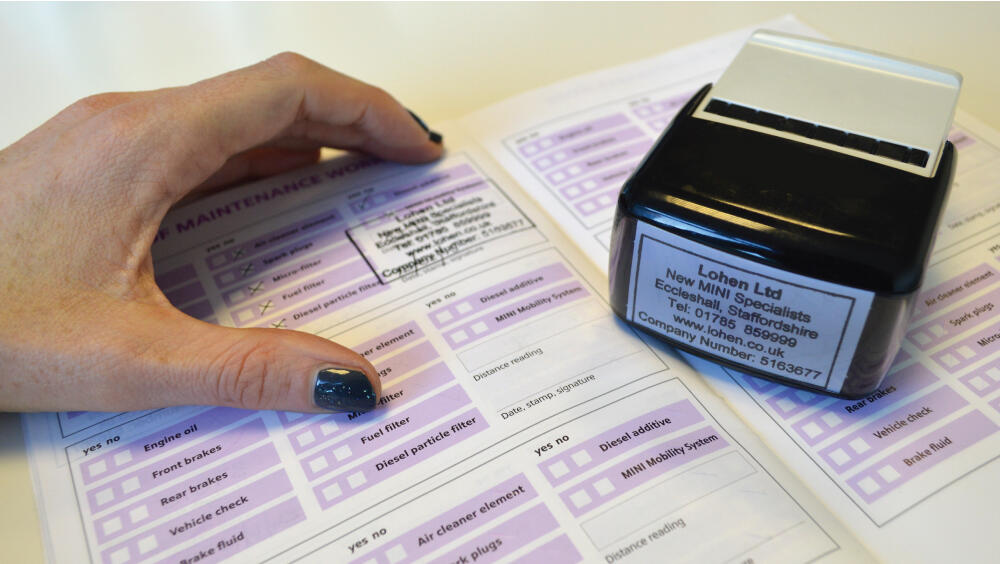

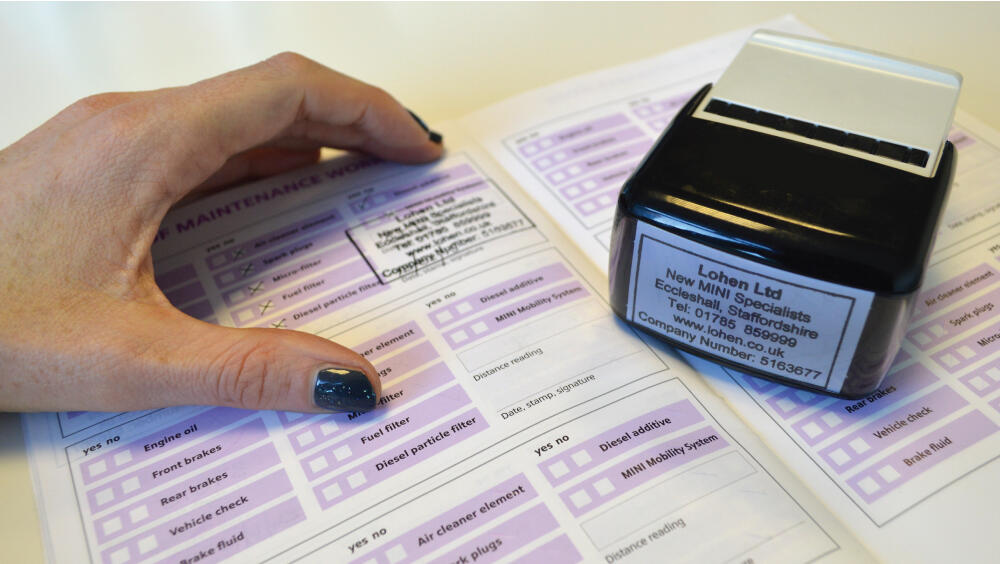

Did you know Lohen can organise an MOT for your MINI? We have access to MOT facilities on-site and can combine it with servicing or upgrade work. Should your MINI fail and require work to pass its MOT, Lohen carries a large stock of servicing and maintenance parts to get the job done, so we’ll have you back motoring as soon as possible.

Contact us if you have any MINI servicing or MINI MOT questions.